Battery Build, Part 1

Jun. 29 2023Over the last day or two I’ve been working on the battery build for TPB.

For this build, I’m recovering some Molicel P26A cells I’ve used a while back. The old pack was a 14s14p build – mad amount of power. What’s left here is half of that pack. Sad to see all the nice copper work go, but a 7S pack sitting around isn’t doing me any good :D

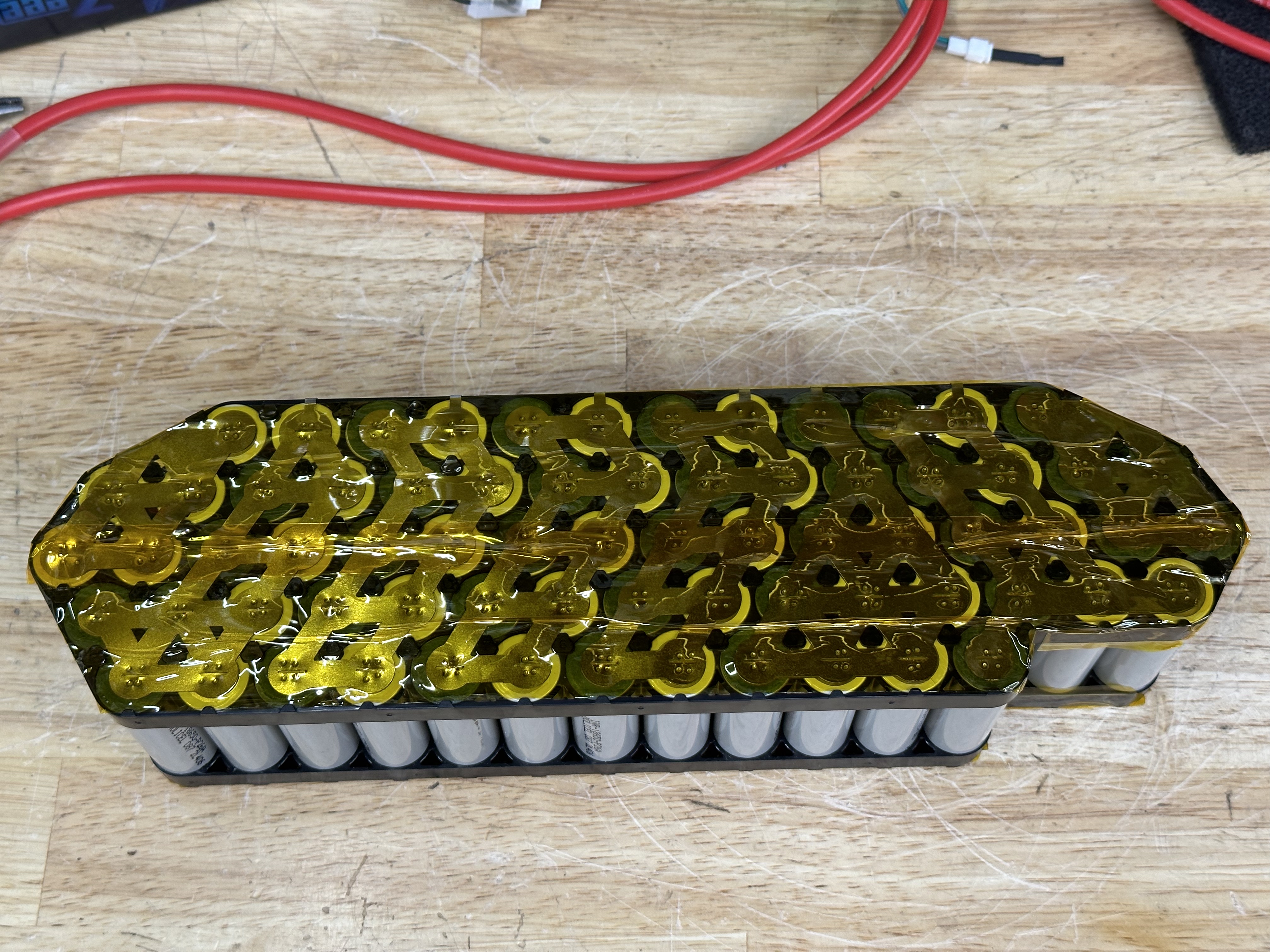

For this build, I’m sticking with 14s, but using a smaller, more standard Polly DP-6 case. This gives me space for 5 parallel cells per group for a total of 70 cells. However, since this pack is normally designed for a 35A BMS, that’s a bit too low for my needs. All the nickel here has been multi-layered so that it’ll be able to handle the full potential of these cells; well into the 80-100A power region.

Time to get into it; started tearing off all the old nickel and copper strips. I managed to create an explosive short only once while taking it apart, yay!

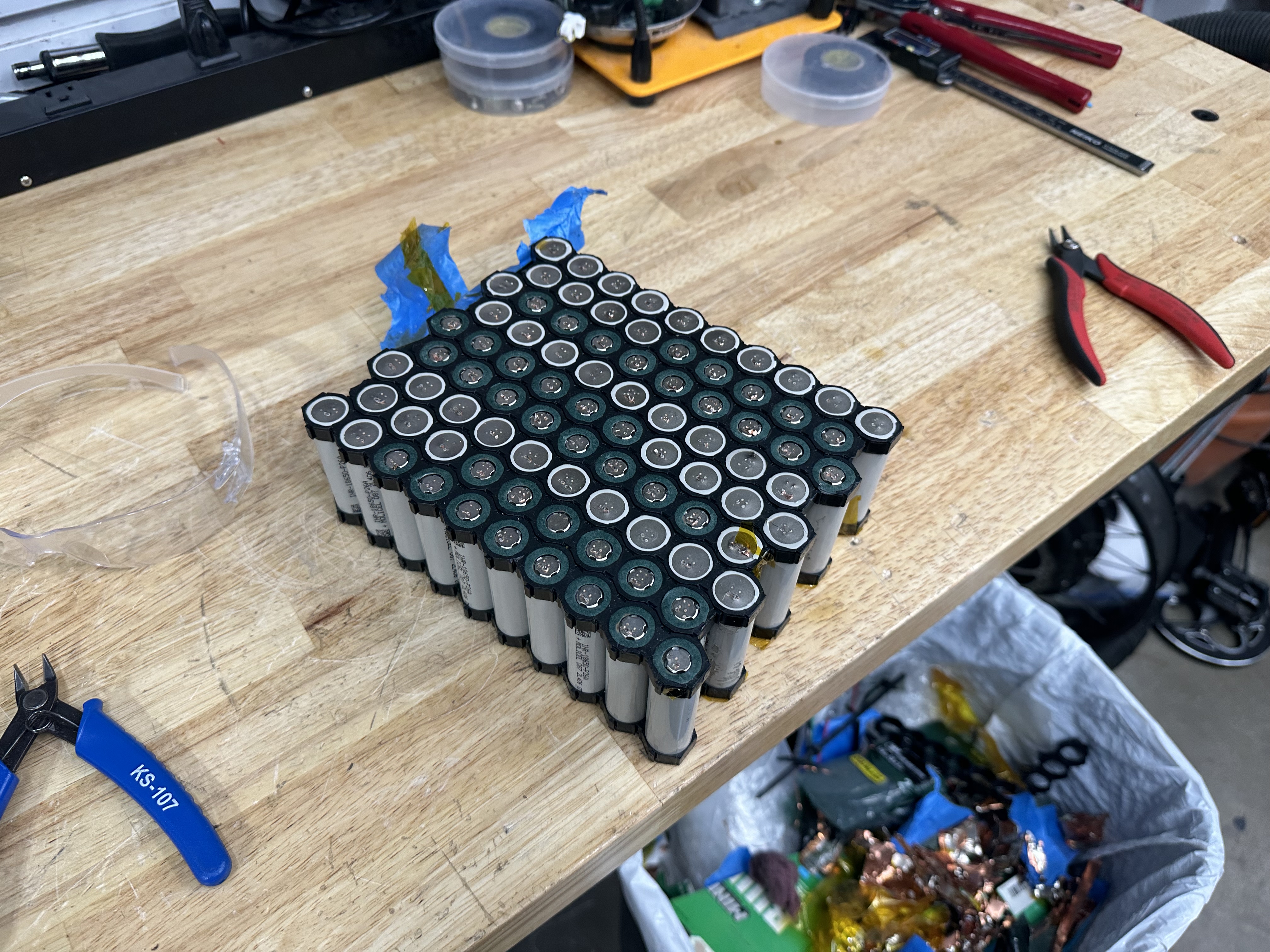

After this part, Lia helped me hammer apart all the cell holders (gently, I promise) and salvage the cells.

The next step is to populate the cell holder.

I had a good bit of…forceful encouragement getting the cells to fit – they are just sliiiightly too large on the positive end. Regardless, on to the spot welding:

While welding the first side, I always start with the side that does not have the neg/positive ends on it. Here you can see how I use some drill bit cases to rest my hands while I weld. Additionally, while welding the first side, you don’t have to worry about accidentally creating a short as there are no connections on the other side, so no special care is taken to “cover up” any areas of the battery.

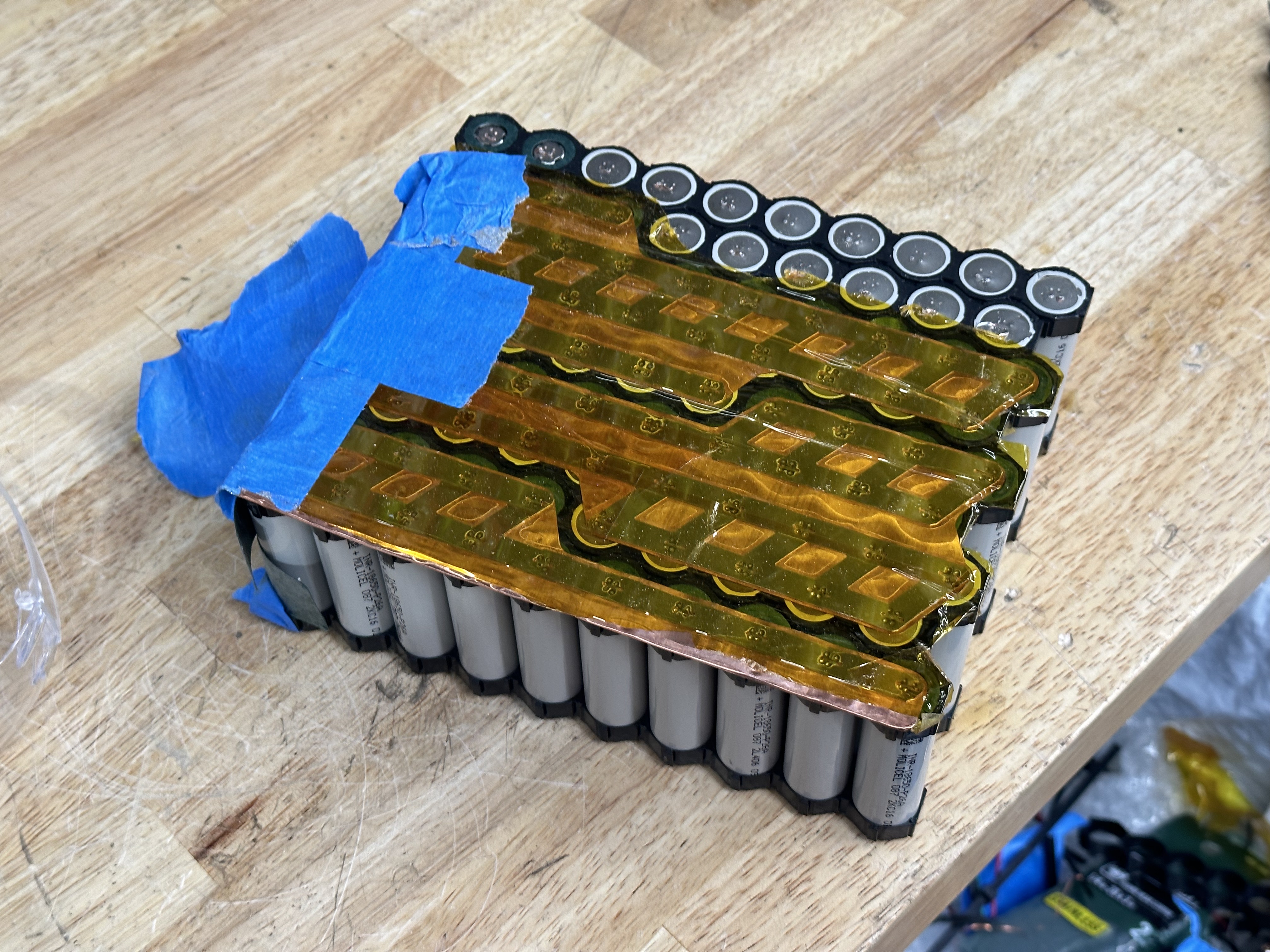

With that side done, it’s in to “The Danger Zone” now. While welding this side, if you place some nickel in the wrong spot, you can create a bunch of fireworks or simply heat up some nickel and burn your fingers real nicely. Not that I know this from first hand experience or anything.

Anyway, some judicious application of blue tape ensures reduces the possibilities of this tremendously.

And with that side all taken care of, the primary task of welding the battery is complete. A quick double check of all the balance leads with a multimeter and covered up in Kapton tape – we’re good to go.

For some extra fun, here is a video where I’m welding together the end tabs (where the negative and positive wires solder on) so that they act as a single tab.

Gotta love some sparks in the face; wear your eye protection (I sure did!)

More from The Purple Bike:

- Overview (Jun 1, 2023)

- Battery Build, Part 1 (Jun 29, 2023)

- Battery Build, Part 2 (Jun 30, 2023)

- Wiring & Tuning (Jul 1, 2023)